SERVICES

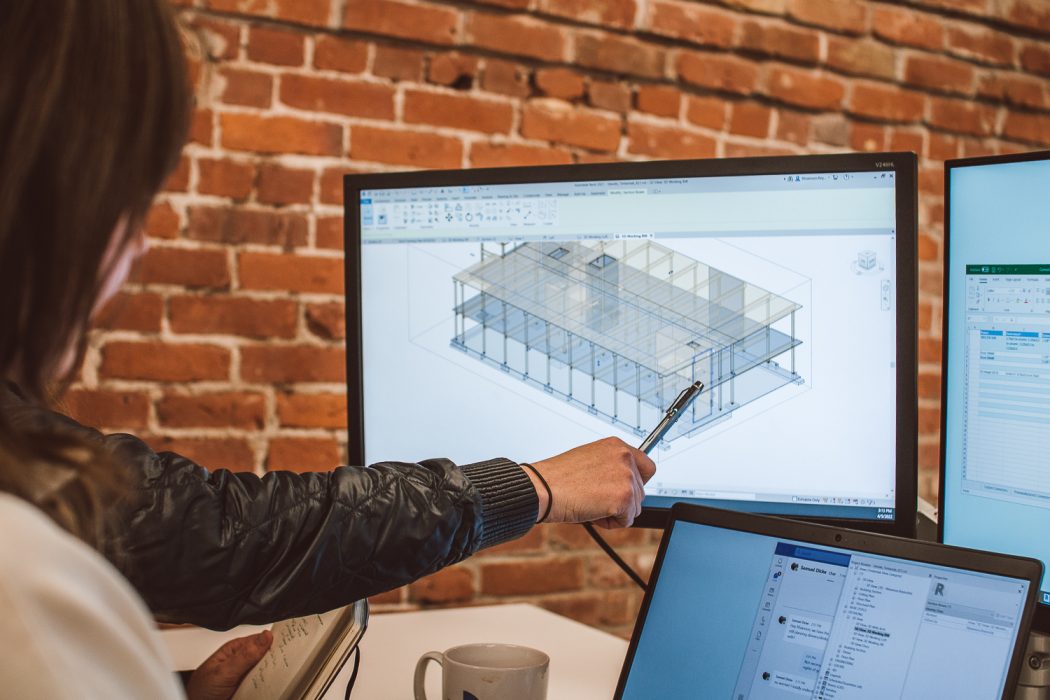

Digital Construction

Our Digital Construction team evolves a mass timber design into fabrication-level information used to prefabricate a kit-of-parts off-site. With deep expertise in the digital construction process, we translate intricate designs into precise fabrication instructions, unlocking new levels of efficiency, accuracy, and customization. By harnessing the power of this technology, we bridge the gap between architectural vision and physical structure, ensuring that every timber component is precisely crafted to fit seamlessly in the construction process.

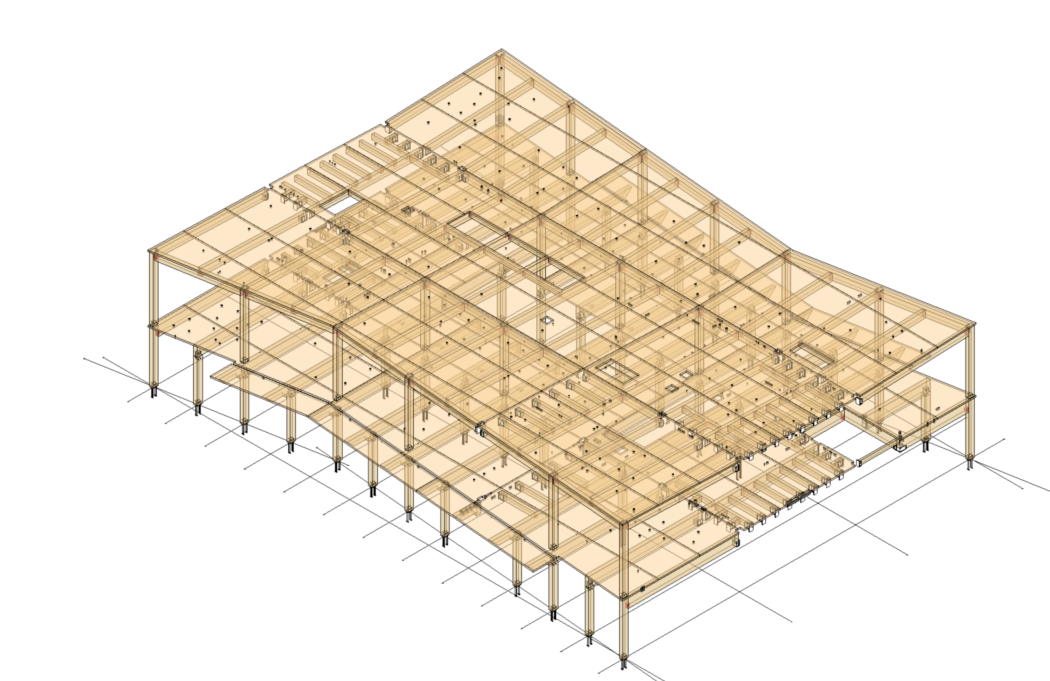

FABRICATION MODELING

Linking the design to construction, we build a model to millimeter-precision that accounts for manufacturing and installation tolerances for the timber, and other materials with which the timber interacts. This process raises awareness of complex construction interactions in preparation for the fabrication of timber components, such as opposing structural elements with varying tolerances, architectural finishes, devices and equipment, and installation requirements.

Our team is proficient in the virtual design and construction process and works closely with our CNC operators to ensure the detailed quality of our engineered wood products. Information from these models produced quantities for estimating and procurement, established sequencing for installation and fabrication, described geometry and component parts for use in their manufacturing control system, and communicated progress or predicted labor requirements.

BUILDING SERVICES INTEGRATION

To harness the full prefabrication potential of mass timber, we seek to integrate all penetrations for mechanical, electrical, plumbing, and fire sprinkler systems, and work with trade partners to ensure their information is integrated into our model. Why? Because a CNC machine can do in 1 minute what it would take a carpenter 1 hour to do on-site, without the safety risk. The end result is an efficient installation of structure and follow-on trade work, both interior and exterior, producing the schedule savings that we attribute to mass timber buildings.

ACHIEVING ARCHITECTURAL INTENT

Our approach to 3D modeling focuses on how the space will look in its final condition. We collaborate with the Architect to understand the design intent for the finished space, meticulously organizing services that are surface-mounted to the ceiling to ensure an uncluttered aesthetic. This involves close coordination with other trade partners so that we not only avoid clashes in the field, but we ensure elegance.

Return to Services